Streamlining electronic assembly lines is critical for manufacturers looking to improve production output and minimize operational costs. To achieve this, a multifaceted approach encompassing robotization and process optimization is essential. Implementing smart sensors to track real-time performance metrics enables predictive maintenance, minimizing downtime and ensuring smooth production operation. Furthermore, leveraging data analytics to identify bottlenecks and areas for enhancement allows for continuous process refinement, leading to a more efficient and optimized assembly line.

- Embracing Industry 4.0 principles such as the Internet of Things (IoT) and cloud computing can provide valuable insights into production processes, enabling data-driven decision-making and further improvement.

- Committing in skilled workforce training programs that focus on automation technologies and process improvement methodologies is crucial for maximizing the benefits of a modernized assembly line.

- Establishing a culture of continuous improvement through regular process reviews, employee feedback mechanisms, and a commitment to innovation can cultivate a high-performing and adaptable electronic assembly environment.

Optimizing SMT Processes

Successful adoption of Surface Mount Technology (SMT) hinges on adhering to established best practices. This involves meticulous attention to detail throughout the entire process, from component selection and board design to soldering techniques and quality control measures. A robust understanding of material properties, soldering parameters, and environmental factors is crucial for achieving reliable and high-performing assemblies.

Effective SMT practices encompass a range of key areas: ensuring proper component placement accuracy, minimizing solder defects through meticulous cleaning and flux management, implementing robust quality control protocols for inspection and testing, and adhering to industry standards for ESD prevention.

- Additionally, continuous improvement initiatives have a vital role in enhancing SMT processes. This involves collecting data, identifying areas for optimization, and implementing process changes to reduce defects and improve overall efficiency.

Automated Optical Inspection (AOI) in Electronics Manufacturing

Automated Optical Inspection optical inspection systems play a crucial role in modern electronics manufacturing. These sophisticated systems utilize high-resolution cameras and advanced algorithms to analyze printed circuit boards (PCBs) and other electronic components for defects. AOI machines can detect a wide range of anomalies, including missing parts, ensuring the production of high-quality electronics. The process typically involves scanning PCBs at various stages of assembly, allowing manufacturers to identify and rectify issues promptly. The benefits of AOI include increased productivity, reduced rework rates, and improved product reliability.

- AOI systems can be customized to meet specific industry standards

- Real-time data analysis enables quick identification and resolution of quality problems.

- Integration with other manufacturing systems enhances process efficiency and traceability.

Design for Manufacturability (DFM) Considerations considerations

Design for Manufacturability (DFM) is a crucial step in the product development cycle that aims to optimize the manufacturing process. By integrating manufacturability requirements into the design phase, engineers can reduce production costs, improve product quality, and accelerate time-to-market. DFM encompasses a wide range of approaches, such as standardization of components, mechanization of processes, and careful selection of materials that are easy to process.

- A key element of DFM is ensuring that the design can be fabricated efficiently and accurately.

- This involves assessing the design for potential production challenges, such as complex geometries, intricate assemblies, or demands for tight tolerances.

- Coordination between designers and manufacturing engineers is essential to realize successful DFM.

By proactively addressing manufacturability concerns during the design phase, companies can derive significant advantages. DFM leads to reduced production costs, improved product quality, faster lead times, and increased user satisfaction.

Managing Supply Chains for Electronics Production

Efficient supply chain management plays in the electronics production industry. The intricate network of suppliers, manufacturers, distributors, and retailers requires tight coordination to ensure timely delivery of high-quality components and finished products. From sourcing raw materials to manufacturing complex circuit boards, every stage demands meticulous planning and execution.

Effective supply chain management in electronics production encompasses several key aspects, including:

- Improving Procurement Processes

- Inventory Management

- Logistics

- Performance Control

Through implementing sophisticated technologies, businesses can improve visibility, traceability, and adaptability throughout the supply chain. This consequently leads to reduced lead times, lower costs, and increased customer satisfaction in the highly competitive electronics market.

The Future of Electronics Manufacturing: Trends and Innovations

The gadget manufacturing landscape is constantly evolving, driven by requirements for smaller, faster, and more powerful devices. Emerging technologies are shaping the industry, offering remarkable advancements in production methods and materials. One key trend is the implementation of automation to enhance manufacturing processes, enhancing productivity and lowering costs.

Moreover, the rise of additive manufacturing is disrupting the way electronics are created. This process allows for customized device fabrication and the manufacture of complex structures that were previously unachievable.

- Responsible manufacturing practices are also gaining traction in the electronics industry. Companies are implementing measures to decrease their ecological footprint, harnessing sustainable energy sources and supporting recycling initiatives.

- Deep Learning is playing an increasing role in electronics manufacturing, streamlining tasks such as quality assurance, proactive repairs, and yield improvement.

Looking ahead, get more info the future of electronics manufacturing holds immense potential. As these trends continue to converge, we can foresee a highly advanced and sustainable industry that provides innovative and impactful products to meet the ever-changing needs of consumers.

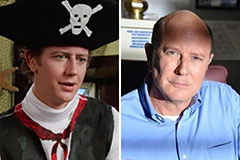

Judge Reinhold Then & Now!

Judge Reinhold Then & Now! David Faustino Then & Now!

David Faustino Then & Now! Macaulay Culkin Then & Now!

Macaulay Culkin Then & Now! Mason Reese Then & Now!

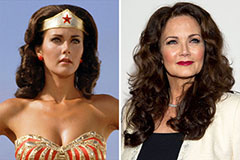

Mason Reese Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now!